Armoured cable is a type of electrical cable that is encased in a protective sheath of metal armour. This protective sheathing is designed to provide protection against mechanical damage, such as crushing and abrasion, as well as providing additional insulation. It has become an essential component of many industries for its durability and flexibility.

What is Armoured Cable?

Armoured cable is a type of electrical wiring that is encased in a protective covering made of metal or plastic. It is most commonly used in industrial and commercial settings where there is an increased risk of damage to regular electrical wiring. The armoured casing helps protect the wiring from water, corrosion, rodents, and other elements that could cause damage over time.50mm 4 core armoured cables Philippines are often used in commercial settings including factories, warehouses, office buildings, and power plants as well as residential applications such as single family homes and apartments. They are also very useful in outdoor applications where they can be exposed to harsh weather conditions with little risk of failure due to their resistance to water damage and corrosion. In addition, they are often used for underground projects such as highways and subways where the cables would otherwise be exposed to extreme temperatures or ground movement over time which could affect performance if an unprotected cable was used instead. When selecting 95mm 3 core armoured cable for a specific project it is important to consider several factors including environment exposure, temperature rating, voltage rating, size/gauge of conductor wire required for the application at hand as well as any applicable building codes that must be adhered to when installing these types of cables. Additionally it's important to ensure that you have chosen an appropriately rated product based on your needs; choosing an undersized or lightweight product may result in reduced lifespan while going too large may result in unnecessary costs with little added benefit. Finally make sure you have selected the right material depending on your needs; some materials offer better fire resistance while others may provide greater strength or flexibility depending on your application requirements.

Types of Armoured Cable

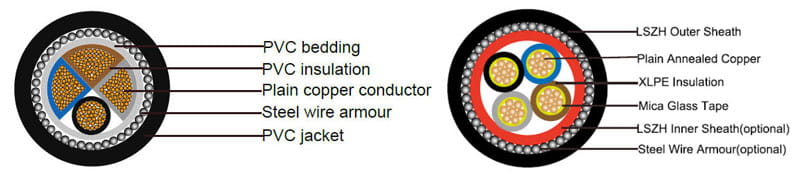

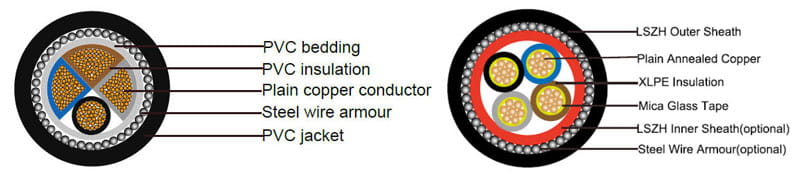

Armoured cable is a type of electrical wiring that is encased in a protective sheath. This type of cable is often used in industrial, commercial and residential applications where the cable needs extra protection from damage and tampering. The outer layer of 5 core armoured cable is made up of metal strips or wires that are woven together to form a tough, flexible armour. The most common types of armoured cable include steel wire armoured (SWA) cable and aluminium wire armoured (AWA) cable. SWA cables are constructed using galvanised steel wires which are woven around the inner electrical core. This provides excellent protection against impact, abrasion, and moisture. SWA cables have a high resistance to heat, making them suitable for use in areas where there is significant temperature variation throughout the day. Additionally, SWA cables are extremely durable, withstanding external pressure from any direction without compromising their integrity or performance. AWA cables are similar to SWA cables but instead use aluminium wires as their protective sheath. AWA cables offer similar levels of physical protection to SWA cables but they possess higher levels of electrical shielding capabilities due to the additional conductivity provided by the aluminium wires. AWA cables also benefit from higher flexibility than SWA cables and can be more easily bent into complex shapes if needed for unique installation requirements. Both types of 4 core armoured cable provide reliable performance and long-term durability when installed correctly; however, it’s important to choose the right type depending on your application needs and requirements as each type has its own advantages and disadvantages. It’s also important to consider factors such as environmental conditions (temperature range, humidity etc.), fire safety ratings and voltage rating before selecting an 3 core armoured cable for your project or installation.

Advantages and Disadvantages of Armoured Cable

Armoured cable is a type of electrical wiring that is enclosed in a flexible metal sheath. This sheath provides protection against physical damage and environmental hazards, such as moisture and temperatures that are outside the recommended range. The armour also serves to reduce electromagnetic interference (EMI) from external sources. The advantages of using 120mm 3 core armoured cable with best price in Philippines include increased safety, durability, and protection from EMI. The metal sheathing acts as an effective shield against physical and environmental damage, making it ideal for use in harsh environments or areas with extreme temperatures. Additionally, the shielded construction reduces external interference, providing reliable data transmission and improved signal quality. However,5 core armoured cable does have some drawbacks. It can be more costly than other types of wiring due to its additional protection layers. Additionally, armoured cable can be difficult to install due to its rigid construction and requires specialized tools for cutting or splicing. Despite these disadvantages,3 core armoured cable remains a popular choice for many applications where safety and reliability are essential factors. It is often used in underground systems such as oil rigs and subways; industrial settings such as factories; or marine environments like ships or oil platforms where extreme temperature changes or corrosive elements may be present.

Applications of Armoured Cable

Armoured cable is a type of wiring used as an electrical conductor in various applications. It is designed to be more durable than standard wiring and is commonly found in industrial or commercial settings, such as factories and warehouses. Its construction consists of two or more insulated conductors that are wrapped in metal armouring, usually steel or aluminum. This additional armoured layer helps to protect the wiring from external damage, making it ideal for hazardous locations or areas subject to physical impact. The types of 150mm 3 core armoured cable in Philippines available depend on its intended use and environment. The most common types include flexible conduit (flex), steel tape armour (STA) and spiral wire armour (SWA). Flexible conduit is suitable for indoor applications where there are tight corners and bends, while STA has higher levels of protection from mechanical hazards and SWA offers maximum protection from environmental factors such as moisture and fire. The main advantage of using 2 core armoured cable is its durability, which makes it highly resistant to external damage that can occur through accidental contact, abrasion or corrosion. Additionally, its thicker insulation layer helps prevent short circuits by preventing electric current leaking out into the surrounding environment - this can also improve energy efficiency as less energy will be lost through heat dissipation or radiation. Furthermore, 3 core armoured cables are easier to install than non-armoured cables due to their robust construction making them ideal for difficult-to-reach places such as underground tunnels or high-rise buildings. Armoured cable can be used in a variety of applications including in underground power networks, elevators, marine vessels, oil rigs and railways. It is also often seen in residential homes providing access to electricity points throughout the building and powering appliances such as stoves, dishwashers and washing machines. When selecting the right type of armoured cable for a particular application there are several factors to consider such as voltage rating, temperature range and maximum current flow capacity (ampacity). As different types of armoured cable have different capabilities it’s important to select a product that meets the specific requirements for your application - if unsure then seek advice from an expert installer who will be able to advise what type of product will best suit your needs. In addition, when installing armoured cable make sure it’s correctly terminated so that you get the best performance - if not installed correctly then you may experience problems with poor signal integrity or electrical safety issues.

Tips for Selecting the Right Armoured Cable with best price

When selecting the right armoured cable, it is important to consider a few factors. The first thing to consider is what type of environment the cable will be used in. If it will be exposed to extreme temperatures or other environmental conditions, then you may need specialised cables with additional insulation and protection. For example, if the cable will be used outdoors in areas prone to rain or snow, then you may need an 4 core armoured cable with a water-resistant jacket. It's also important to consider the type of load and voltage that the 5 core armoured cable will need to carry. Heavier loads require heavier-duty cables and higher voltages require more insulation. Additionally, some applications may require special certifications like UL ratings for fire safety or CSA ratings for electrical safety. Make sure these certifications are met when selecting an 3 core armoured cable for your application. The most common material used for armoured cables is steel, but other materials such as aluminium or plastic can also be used depending on the specific requirements of your application. Steel provides excellent protection from mechanical damage but it is heavier than other materials so it may not be ideal for certain applications where portability is needed. Aluminium offers lighter weight protection but does not offer as much rigidity as steel does so it may not be suitable for certain applications as well. Finally, make sure you pay close attention to the installation process when installing an armoured cable. Many manufacturers provide detailed installation instructions which should always be followed closely in order to ensure safe operation and reduce potential risks associated with improper installations.

Armoured Cable Installation

Armoured cable is a type of electrical wiring which is encased in a protective sheath of armouring to prevent damage and any electrical leakage. The armoured cable is usually made of steel or aluminium, although some variations can be made from plastic or other materials. It is typically used in areas where there are corrosive substances and extreme temperatures, as the armouring helps to protect the cables from these elements. When installing armoured cable, it is important to ensure that all connections are secure and tight to prevent any accidental contact with electricity. Additionally, any connection points should be sealed properly so that moisture does not enter the system. It's also recommended to use a cable lacing tool when installing 4 core armoured cable Philippines to ensure that the connections are uniform and tight. Additionally, it's important to connect all wires in accordance with local regulations, such as adhering to proper wire gauge size guidelines. Finally, it's essential that all cables have adequate support so that they are not subjected to excessive strain or tension during installation. Another important factor when installing armoured cable is using the right tools for the job. This includes using special cutting tools designed specifically for 3 core armoured cables, as well as crimping tools for making secure connections. Additionally, when working with these types of cables it’s important to take safety precautions such as wearing protective gloves and eye protection while handling them. Finally, choosing the right type of armoured cable Philippines for your needs is essential in ensuring maximum protection and performance from your installation. Different types of armoured cables have different levels of protection against corrosion and heat resistance; selecting a type based on your specific requirements will help you get the most out of your installation.

Conclusion

Armoured cables are an essential element of many electrical systems, offering greater protection against mechanical damage and improved safety compared to non-armoured alternatives. They come in various types, each suited for different applications and environments, so it is important to select the right armoured cable witn best price for the job. When installing armoured cables Philippines, it is important to take into consideration factors such as the environment, temperature and potential sources of mechanical damage. With proper selection and installation, 3 core armoured cables can provide a reliable and safe connection for your electrical system.