64/110kv high voltage cable is an essential part of the electrical infrastructure in many industrial, commercial, and residential settings. This type of cable is designed to be able to safely transmit high-voltage electricity while providing reliable and durable performance. In order to meet the ever-increasing demand for power distribution and maintenance, 64/110kv cable has become more widely used in recent years. The use of this type of cable is increasingly becoming a choice among professionals, due to its superior safety features and long-term functionality.

64/110 kv high voltage cable Feature

64/110kv cable is a high voltage power cable manufactured for industrial and commercial applications. With its insulation rated for up to 110 kilovolts (kV), 64/110kv cable is designed to safely transmit power between two points, typically from a main distribution point to customer’s facilities. The 64/110kv cable also has a copper or aluminum conductor that allows the transfer of higher current with less voltage losses, allowing it to be used in long-distance transmission. For optimal electrical performance, 64/110kv cable offers improved insulation properties compared to other cables, enabling it to carry higher voltages without experiencing electrical breakdowns. This type of high-voltage cable also features an additional shielding layer that provides further protection from external interference and ensures safe operation at higher levels of electrical stress. Additionally, 64/110kv cable can be produced in various sizes and shapes depending on the application requirements.

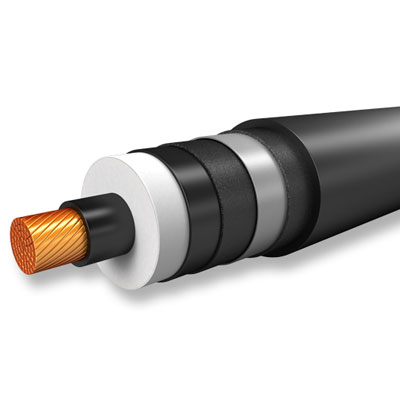

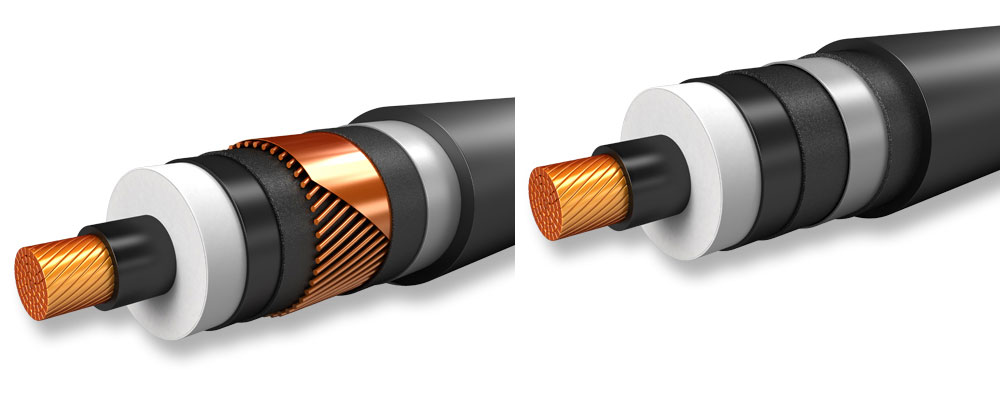

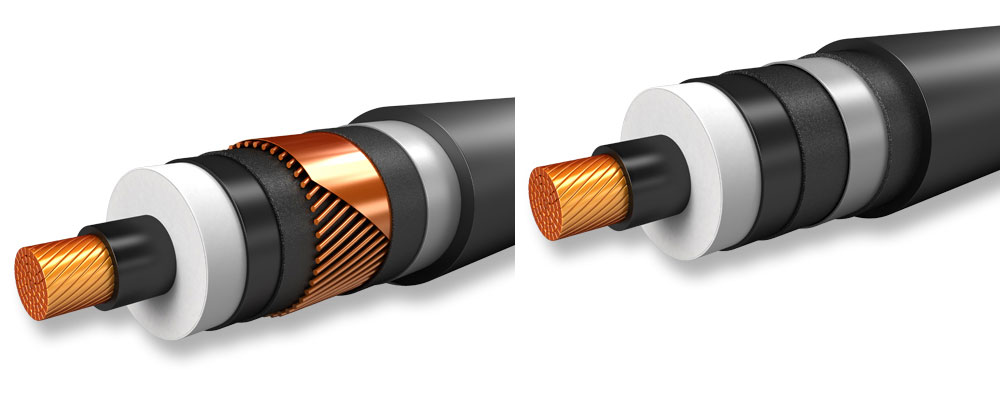

64/110kv hv power cable construction

The construction of a 64/110kv cable is an important factor in its performance. A high voltage cable must be designed to withstand extreme temperatures, high electrical stress and any mechanical stresses that may arise during installation or operation. 64/110kv cable consists of an inner conductor, insulation, outer sheath and protective layers. The inner conductor is usually made of copper or aluminum and is responsible for the carrying current. It must be highly conductive, strong enough to resist mechanical stresses, heat resistant and corrosion resistant. The insulation layer provides electrical protection by isolating the inner conductor from other conductors or objects that may come into contact with it. This layer typically consists of a dielectric material such as polyethylene, cross-linked polyethylene (XLPE) or ethylene-propylene rubber (EPR). The outer sheath provides protection for the inner layers from moisture, dirt, abrasion and any other external damage. It is usually made from materials such as PVC or low smoke zero halogen (LSZH). Additionally, there are also additional protective layers which provide additional protection from UV rays and fire resistance. These are usually made from materials such as silicone rubber or mica tape. To ensure the highest quality performance of a 64/110kv cable, our 64/110kv hv power cable must be tested in accordance with relevant industry standards and regulations. Testing includes high voltage tests on the entire cable assembly to check its ability to withstand electric shocks and high temperature.

64/110kv hv power cable specification

|

64/110 (123) kV High Voltage Power Cable With Copper Wire Screen Constructional & Electrical Data |

|

Conductor |

Insulation |

Metallic Screen |

Outer Jacket |

|

Nominal Area |

Max. DC Resis- tance at 20 °C |

Max. AC Resis- tance at 90 °C |

Nominal Thickness of Insulation Layers |

Electro- static Capaci- tance |

Nominal Area of Copper Wires(1) |

Short Circuit Capacity (1 Sec.)(2) |

Nominal Thick- ness |

Approx. Overall Diameter |

Approx. Overall Weight |

|

Cond. Screen |

XLPE |

Ins. Screen |

|

mm2 |

Ω / km |

Ω / km |

mm |

mm |

mm |

μF / km |

mm2 |

kA |

mm |

mm |

kg / m |

|

300 R |

0.0601 |

0.0787 |

1.2 |

15 |

1 |

0.167 |

95 |

15.3 |

3.5 |

67.9 |

6.47 |

|

400 R |

0.047 |

0.0627 |

1.2 |

15 |

1 |

0.18 |

95 |

15.3 |

3.5 |

70.5 |

7.41 |

|

500 R |

0.0366 |

0.0502 |

1.2 |

15 |

1 |

0.196 |

95 |

15.3 |

4 |

74.9 |

8.79 |

|

630 R |

0.0283 |

0.0407 |

1.2 |

15 |

1 |

0.213 |

95 |

15.3 |

4 |

78.4 |

10.21 |

|

800 R |

0.0221 |

0.0338 |

1.2 |

15 |

1 |

0.232 |

95 |

15.3 |

4 |

82.4 |

12.17 |

|

1000 S |

0.0176 |

0.024 |

1.5 |

15 |

1.2 |

0.276 |

95 |

15.3 |

4 |

92.1 |

14.74 |

|

1200 S |

0.0151 |

0.0211 |

1.5 |

15 |

1.2 |

0.295 |

95 |

15.3 |

4.5 |

97.1 |

17 |

|

1400 S |

0.0129 |

0.0185 |

1.5 |

15 |

1.2 |

0.305 |

95 |

15.3 |

4.5 |

99.1 |

18.99 |

|

1600 S |

0.0113 |

0.0168 |

1.5 |

15 |

1.2 |

0.323 |

95 |

15.3 |

4.5 |

103.1 |

20.72 |

|

2000 S |

0.009 |

0.0143 |

1.5 |

15 |

1.2 |

0.347 |

95 |

15.3 |

4.5 |

108.1 |

24.42 |

|

2500 S |

0.0072 |

0.0125 |

1.5 |

15 |

1.2 |

0.384 |

95 |

15.3 |

4.5 |

116.1 |

29.99 |

|

64/110 (123) kV High Voltage Power Cable with Lead Sheath Constructional & Electrical Data |

|

Conductor |

Insulation |

Metallic Screen |

Outer Jacket |

|

Nominal Area |

Max. DC Resis- tance at 20 °C |

Max. AC Resis- tance at 90 °C |

Nominal Thickness of Insulation Layers |

Electro- static Capaci- tance |

Nominal Thickness of Lead Sheath(1) |

Short Circuit Capacity (1 Sec.)(2) |

Nominal Thick- ness |

Approx. Overall Diameter |

Approx. Overall Weight |

|

Cond. Screen |

XLPE |

Ins. Screen |

|

mm2 |

Ω / km |

Ω / km |

mm |

mm |

mm |

μF / km |

mm |

kA |

mm |

mm |

kg / m |

|

300 R |

0.0601 |

0.0787 |

1.2 |

15 |

1 |

0.167 |

2.4 |

10.6 |

3.5 |

68.3 |

10.4 |

|

400 R |

0.047 |

0.0627 |

1.2 |

15 |

1 |

0.18 |

2.5 |

11.5 |

3.5 |

71.1 |

11.78 |

|

500 R |

0.0366 |

0.0502 |

1.2 |

15 |

1 |

0.196 |

2.6 |

12.6 |

4 |

75.7 |

13.7 |

|

630 R |

0.0283 |

0.0406 |

1.2 |

15 |

1 |

0.213 |

2.7 |

13.8 |

4 |

79.4 |

15.7 |

|

800 R |

0.0221 |

0.0338 |

1.2 |

15 |

1 |

0.232 |

2.8 |

15.1 |

4 |

83.6 |

18.29 |

|

1000 S |

0.0176 |

0.024 |

1.5 |

15 |

1.2 |

0.276 |

2.9 |

17.7 |

4 |

93.4 |

22.1 |

|

1200 S |

0.0151 |

0.021 |

1.5 |

15 |

1.2 |

0.295 |

3 |

19.2 |

4.5 |

98.6 |

25.09 |

|

1400 S |

0.0129 |

0.0185 |

1.5 |

15 |

1.2 |

0.305 |

3.1 |

20.2 |

4.5 |

100.8 |

27.61 |

|

1600 S |

0.0113 |

0.0168 |

1.5 |

15 |

1.2 |

0.323 |

3.2 |

21.8 |

4.5 |

105 |

30.12 |

|

2000 S |

0.009 |

0.0143 |

1.5 |

15 |

1.2 |

0.347 |

3.4 |

24.4 |

4.5 |

110.4 |

35.09 |

|

2500 S |

0.0072 |

0.0125 |

1.5 |

15 |

1.2 |

0.384 |

3.6 |

27.8 |

4.5 |

118.8 |

42.39 |

64/110 kv high voltage cable application

64/110kv high voltage cable can easily transmit power over long distances without significant loss. This makes them ideal for the energy sector, especially when it comes to the reliable delivery of energy to remote locations. In addition to the transmission and distribution of electricity, these high voltage cables can also be used for other applications. For instance, they can be used in data centers, where their resilience and power transfer capabilities are important factors. Additionally, some 64/110kv cables are suitable for underground use due to their enhanced durability and water resistance properties. The most common application for 64/110kv cables is in substations and power plants, where they provide reliable connection between generators and other components of the electrical system. Moreover, these cables have a stable dielectric strength, meaning that they don’t suffer from temperature fluctuations or environmental factors such as moisture or dust. This ensures that the connection remains stable throughout its lifetime while also reducing maintenance costs. Finally, these types of high voltage cables have excellent safety features that make them safe to use in hazardous areas where there is potential danger from electric shocks or fires. They are also designed with multiple layers of insulation which helps reduce electromagnetic interference and prevents any arcing or sparking which could result in an explosion or fire hazard. All these features make 64/110kv cables an ideal choice for many applications requiring reliable power transfer and protection against dangerous conditions.

64/110 kv high voltage cable price list

When it comes to high voltage cables, the price is one of the most important aspects to consider. When looking for a 64/110kV cable, you should compare prices from different suppliers in order to get the best deal. Prices will vary depending on the type and quality of cable, as well as any other services offered by the supplier. The price of a 64/110kV cable can range from several hundred dollars to thousands of dollars, depending on its features and specifications. Generally speaking, higher voltage cables will cost more than lower voltage cables. Similarly, the length of the cable may also affect the overall price; longer lengths may require additional materials and labor to complete installation, thus adding to the total cost. When purchasing 64/110kV cables, keep in mind that quality is important for both safety and efficiency reasons. Make sure that your supplier can provide certifications or guarantees that their product meets industry standards in terms of performance and safety.

In conclusion, 64/110kv high voltage cables are able to provide a safe and reliable power option for many applications, thanks to their strong construction and wide range of features. They come in a variety of price ranges, allowing customers to choose the best option for their needs. Additionally, these cables are incredibly versatile and can be used in a variety of applications with great success. Ultimately, the 64/110kv cable is an excellent choice for anyone looking for a reliable and affordable high voltage cable solution.