The 76/132kV High Voltage Cable is an important component of the power transmission network, providing reliable and cost-effective electricity to communities and businesses. By utilizing 76/132kV high voltage cable, electricity can be delivered over longer distances with fewer losses. This type of cable is designed for the highest voltage requirements and has a variety of insulation materials and designs to meet those needs. With its high performance, reliability and easy installation, the 76/132kV cable provides a dependable source of power for many applications.

76/132kv High Voltage Cable Feature

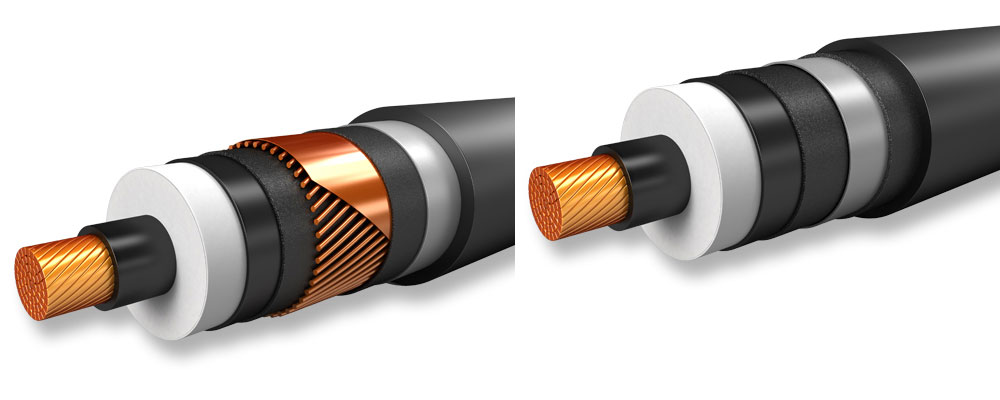

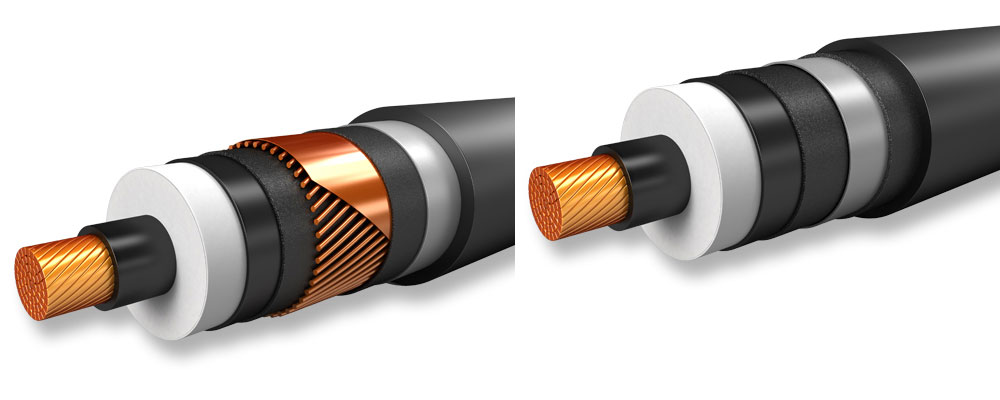

76/132kv high voltage cables are a type of electrical cable used for transmitting electricity at high voltages. These cables are specially designed to be stronger and more reliable than lower voltage cables, and as such they are suitable for applications where higher voltage is required. They also provide better electrical insulation than other types of cable, making them safer to use. One of the main advantages is that 76/132kv high voltage cable offers greater flexibility when it comes to installation, making it easier to install in both underground and overhead applications. Additionally, these cables can be used in both wet and dry environments thanks to their strong insulation materials. 76/132kv xlpe high voltage cables also boast an impressive range of inspection tests that ensure their quality before being put into use. This includes rigorous testing for electrical properties, as well as mechanical strength tests that make sure the cable meets all safety standards before being used in any application. Furthermore, these cables also have a long life expectancy when compared to other types of electrical cables due to their robust construction materials. All in all, 76/132kv high voltage cables provide a reliable solution for any application that requires higher voltages and better insulation than regular electrical cables can offer.

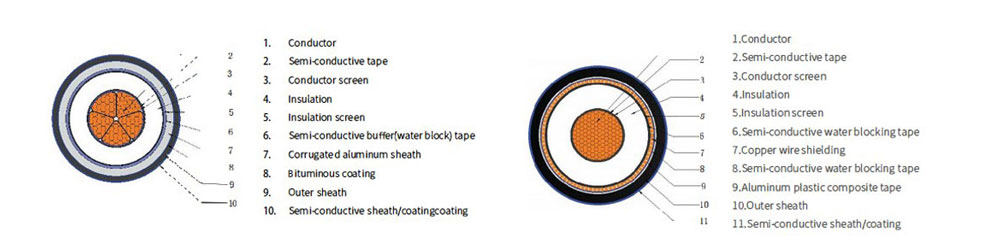

76/132kv High Voltage Cable Specification

|

76/132 (145) kV High Voltage Power Cable With Copper Wire Screen Constructional & Electrical Data |

|

Conductor |

Insulation |

Metallic Screen |

Outer Jacket |

|

Nominal Area |

Max. DC Resis- tance at 20 °C |

Max. AC Resis- tance at 90 °C |

Nominal Thickness of Insulation Layers |

Electro- static Capaci- tance |

Nominal Area of Copper Wires(1) |

Short Circuit Capacity (1 Sec.)(2) |

Nominal Thick- ness |

Approx. Overall Diameter |

Approx. Overall Weight |

|

Cond. Screen |

XLPE |

Ins. Screen |

|

mm2 |

Ω / km |

Ω / km |

mm |

mm |

mm |

μF / km |

mm2 |

kA |

mm |

mm |

kg / m |

|

300 R |

0.0601 |

0.0786 |

1.2 |

18 |

1.2 |

0.148 |

95 |

15.3 |

4 |

75.3 |

7.23 |

|

400 R |

0.047 |

0.0625 |

1.2 |

18 |

1.2 |

0.159 |

95 |

15.3 |

4 |

77.9 |

8.2 |

|

500 R |

0.0366 |

0.0501 |

1.2 |

18 |

1.2 |

0.173 |

95 |

15.3 |

4 |

81.3 |

9.51 |

|

630 R |

0.0283 |

0.0404 |

1.2 |

18 |

1.2 |

0.187 |

95 |

15.3 |

4 |

84.8 |

10.96 |

|

800 R |

0.0221 |

0.0336 |

1.2 |

18 |

1.2 |

0.203 |

95 |

15.3 |

4 |

88.8 |

12.95 |

|

1000 S |

0.0176 |

0.0239 |

1.5 |

18 |

1.2 |

0.24 |

95 |

15.3 |

4 |

98.1 |

15.55 |

|

1200 S |

0.0151 |

0.021 |

1.5 |

18 |

1.2 |

0.256 |

95 |

15.3 |

4.5 |

103.1 |

17.86 |

|

1400 S |

0.0129 |

0.0184 |

1.5 |

18 |

1.2 |

0.264 |

95 |

15.3 |

4.5 |

105.1 |

19.86 |

|

1600 S |

0.0113 |

0.0167 |

1.5 |

18 |

1.2 |

0.28 |

95 |

15.3 |

4.5 |

109.1 |

21.63 |

|

2000 S |

0.009 |

0.0142 |

1.5 |

18 |

1.2 |

0.299 |

95 |

15.3 |

4.5 |

114.1 |

25.37 |

|

2500 S |

0.0072 |

0.0124 |

1.5 |

18 |

1.2 |

0.331 |

95 |

15.3 |

4.5 |

122.1 |

31.01 |

|

76/132 (145) kV High Voltage Power Cable with Lead Sheath Constructional & Electrical Data |

|

Conductor |

Insulation |

Metallic Screen |

Outer Jacket |

|

Nominal Area |

Max. DC Resis- tance at 20 °C |

Max. AC Resis- tance at 90 °C |

Nominal Thickness of Insulation Layers |

Electro- static Capaci- tance |

Nominal Thickness of Lead Sheath(1) |

Short Circuit Capacity (1 Sec.)(2) |

Nominal Thick- ness |

Approx. Overall Diameter |

Approx. Overall Weight |

|

Cond. Screen |

XLPE |

Ins. Screen |

|

mm2 |

Ω / km |

Ω / km |

mm |

mm |

mm |

μF / km |

mm |

kA |

mm |

mm |

kg / m |

|

300 R |

0.0601 |

0.0786 |

1.2 |

18 |

1.2 |

0.148 |

2.6 |

12.7 |

4 |

76.1 |

12.18 |

|

400 R |

0.047 |

0.0625 |

1.2 |

18 |

1.2 |

0.159 |

2.7 |

13.7 |

4 |

78.9 |

13.63 |

|

500 R |

0.0366 |

0.05 |

1.2 |

18 |

1.2 |

0.173 |

2.8 |

14.9 |

4 |

82.5 |

15.52 |

|

630 R |

0.0283 |

0.0404 |

1.2 |

18 |

1.2 |

0.187 |

2.9 |

16.1 |

4 |

86.2 |

17.61 |

|

800 R |

0.0221 |

0.0335 |

1.2 |

18 |

1.2 |

0.203 |

3 |

17.5 |

4 |

90.4 |

20.29 |

|

1000 S |

0.0176 |

0.0239 |

1.5 |

18 |

1.2 |

0.24 |

3.1 |

20.2 |

4 |

99.8 |

24.17 |

|

1200 S |

0.0151 |

0.021 |

1.5 |

18 |

1.2 |

0.256 |

3.2 |

21.8 |

4.5 |

105 |

27.26 |

|

1400 S |

0.0129 |

0.0184 |

1.5 |

18 |

1.2 |

0.264 |

3.3 |

22.9 |

4.5 |

107.2 |

29.83 |

|

1600 S |

0.0113 |

0.0166 |

1.5 |

18 |

1.2 |

0.28 |

3.4 |

24.6 |

4.5 |

111.4 |

32.43 |

|

2000 S |

0.009 |

0.0142 |

1.5 |

18 |

1.2 |

0.299 |

3.6 |

27.3 |

4.5 |

116.8 |

37.53 |

|

2500 S |

0.0072 |

0.0123 |

1.5 |

18 |

1.2 |

0.331 |

3.7 |

30.2 |

4.5 |

125 |

44.58 |

76/132kv High Voltage Cable Price List

76/132kv high voltage cable is an important component for industrial, commercial and residential applications. It is designed to carry a large amount of electrical power over long distances with minimal loss. The cost of a 76/132kv cable will vary depending on the type of cable, the length of the run and the size of the conductor being used. In general, larger conductors with greater cross-sectional area will incur higher costs due to their higher material requirements. The price list for a 76/132kv high voltage cable may include components such as insulated core wires, protective sheathing, non-magnetic metallic armor, terminations and connectors. Depending on the application, additional components such as surge protectors or grounding devices may be required which can add to the overall cost. For example, if a single phase connection is needed then additional wire and connections will need to be added to accommodate this requirement. Additionally, there may be labor costs associated with installation which would also need to be taken into account when determining the total cost of a 76/132kv xlpe high voltage cable system. When comparing different brands or types of cables it is important to consider not only price but also quality and safety features that are included in each offering. Quality features such as fire retardant insulation or UV resistant materials can provide additional protection against damage or failure in extreme conditions while safety features such as ground fault interrupter technology can help prevent accidents related to faulty wiring or equipment malfunctions. Ultimately, selecting the right 76/132kv high voltage cable will depend on finding a balance between cost and performance that meets all your requirements.

76/132kv High Voltage Cable Application

76/132kv xlpe high voltage cable is a power transmission line used to transfer electrical energy at a very high voltage. It is an important part of the electric grid and is used in large-scale industrial, commercial and residential applications. 76/132kv xlpe cables are typically manufactured with insulated copper or aluminum conductors, which are then wrapped in an insulating material such as rubber. One of the most common applications for 76/132kv xlpe high voltage cable is for transferring electrical energy from large power stations to different load centers. This type of power transmission can be either underground or overhead depending on the needs of the application. Underground cables offer a higher level of security and are less likely to be affected by weather conditions than overhead lines. They also require fewer maintenance duties compared to overhead lines. The main benefit of using 76/132kv xlpe cable for transferring electricity at such a high voltage is that it reduces power losses due to resistance. This means that more electricity can be transferred over longer distances without having to increase costs by installing thicker cables with larger cross-sectional areas. Additionally, due to its insulation properties, this type of 76/132kv xlpe cable can be used safely in hazardous environments where other types of cables may be unsuitable. In order to ensure safe operation, specific installation requirements must be followed when installing 76/132kv high voltage cable systems. Different measures such as proper grounding and surge protection must be implemented in order to reduce the risk of fire or electrocution due to direct contact with the electric current or accidental leakage from the system itself.

132kv Underground High Voltage Cable Installation

Underground high voltage cables are used in a variety of applications, including power distribution and transmission, as well as telecommunications systems. Installing such cables requires precision and skill to ensure that they are installed properly and securely. The 132kV underground high voltage cable is especially important due to its ability to carry large amounts of electricity safely across long distances. When installing a 132kV underground high voltage cable, it is important to take into account the particular environment of the installation site. For example, in areas with very sandy soil or those that experience frequent flooding, extra measures must be taken to protect the cables from damage or failure. In addition, it is also necessary to consider the weight of the cable when laying it down and make sure there is enough support provided for it. The installation process itself involves connecting two points by linking them with the cable via an underground trench or ducting system. This requires accurate measurements and calculations in order to ensure that there are no electrical hazards during operation. Alongside this, specialised tools must be used in order to cut through any existing obstacles such as rock or concrete. In some cases additional protection may need to be put in place depending on the specific requirements of the application. Finally, after all connections have been made, testing must occur in order to ensure that everything is working correctly before commissioning the project. This includes conducting electrical tests such as dielectric tests in order to measure insulation resistance and high-potential tests for detecting possible faults between phases or within insulation layers. Once these tests have been passed successfully then the cables can be commissioned and put into operation. In conclusion, installing a 132kV underground high voltage cable requires precision and care throughout every stage of its installation process - from taking environmental conditions into consideration when selecting an appropriate site through to performing thorough testing prior to commissioning.

In conclusion, 76/132kV high voltage cable is an important component of many electrical systems. Its features, price list and applications are essential to consider when choosing the right cable for a particular project. Additionally, the installation of 132kV underground high voltage cable requires specialized skills and knowledge in order to ensure that it is done safely and correctly. Therefore, it is important to have the right resources available when selecting and installing any type of 76/132kV cable.