Home > Logging Cable > Monoconductor >

Monoconductor

| Cable Diameter | 0.258” +0.005” - 0.002” | (6.55mm + 0.13mm -0.05mm) |

| Minimum Sheave Diameter | 14” | (36 cm) |

| Cable Stretch Coeffcient | 2.3 ft/Kft/Klbs | (2.60 m/Km/5KN) |

| Maximum Conductor Voltage | 1,200 VDC | |

| Conductor AWG Rating | 16 | |

| Minimum Insulation Resistance | 1,500 Mega Ω/Kft @ 500VDC | (457 Mega Ω/Km @ 500VDC) |

| Armor Electrical Resistance | 10.0 Ω/Kft | (32.9 Ω/Km) |

|

Cable Breaking Strength Ends Fixed |

6,500 lbs | (28.9 KN) Nominal |

| Maximum Suggested Working Tension | 3,250 lbs | (14.5 KN) |

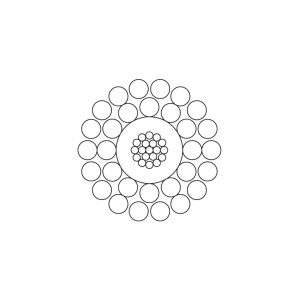

| Number and Size of Wires | ||

| Inner Armor | 12 x 0.0358” | (0.909 mm) |

| Outer Armor | 18 x 0.0358” | (0.909 mm) |

| Average Wire Breaking Strength | ||

| Inner Armor | 252 lbs | (1.12 KN) |

| Outer Armor | 252 lbs | (1.12 KN) |

For the 1N25 S77 price, Please feel free to leave your requirement, We will reply you in 12 hours.

Monoconductor Cable

3-Conductor

4-Conductor

7-Conductor

Any cable inquiry please contact us.

huadong@hdcablegroup.com